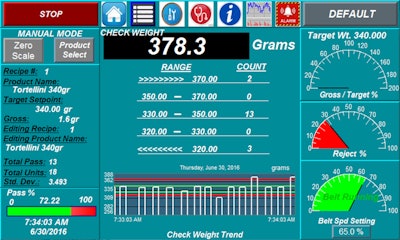

Hardy Process Solutions introduces its groundbreaking approach to checkweigher design, built on a Rockwell Automation platform and using Hardy’s HI4050CW Controller, the Dynamic Checkweigher series delivers performance and flexibility for a user’s current and future product inspection needs.

The Hardy Dynamic Checkweigher is a fully automated system designed to weigh items automatically in-motion. The checkweigher controller can communicate both upstream and downstream across the Connected Enterprise Network. Automated control is done with an embedded Rockwell Automation CompactLogix™ PLC while communicating with the high performance Hardy HI 4050CW checkweighing controller. The resulting checkweighing system can process between 20 to 350 pieces/min.

The new checkweigher family delivers the benefits of open source, off-the-shelf and seamless integration, enabling customers to maintain/enhance their checkweighers to meet future needs. It uses Rockwell Automation’s Premier Integration model using Studio 5000 software and Allen-Bradley components. This approach seamlessly integrates equipment data, control and analytics into plant-level and enterprise networks and all data tags are visible and available on the Connected Enterprise.

Each Dynamic Checkweigher has a stainless-steel base and cabinet for maximum durability and easy washdown. Flexible and accurate, it weighs products of virtually any shape or size in containers such as boxes, cans, bottles, rigid shrink- wrapped packages or flexible packages.

The different checkweigher models include the following:

- Dynamic C: a chain weigher for up to 10 kg (22 lb) of rigid products, such as bottles, cans, cartons operating at up to 350 units/min

- Dynamic S: a small belt weigher for up to 10 kg of pouches, trays, direct foods operating at 200 units/min

- Dynamic I: intermediate belt weigher for up to 22 kg (50 lb) of boxes, tubs, ails and bulk foods operating at 60 units/min

- Dynamic L: a large belt weigher for sacks, kegs, drums, bulk bags up to 90 kg (200 lb) operating up to 50 units/min