In the pharmaceutical industry, Rondo AG is recognized as a supplier of folding cartons, package inserts, as well as system solutions and services. In April 2018, the Allschwil, Switzerland-based company installed the Primefire 106 digital printing system from Heidelberger Druckmaschinen AG.

The digital press represents the final piece in Rondo’s “Supply on Demand” service. “The trends in the pharmaceutical industry are heading towards ever declining runs and shorter delivery times in response to personalized medicine, increasing language and country versions, and much shorter delivery times for medicines,” says Joachim Hoeltz, Rondo AG’s CEO. “Our production consists entirely of secondary packaging. Through process automation and close IT integration we offer our customers a just-in-time service and by doing so help them to optimize their own supply chain.”

Rondo’s Supply on Demand service initiated at the 2017 interpack trade fair. Since then, the company has supplied a key pharmaceutical customer with folding carton orders with very short delivery times. Rondo automated its own workflow and optimized the ERP integration with its customer. The goal of providing small batch sizes in consistently high quality with delivery times of less than a week has been achieved through conventional offset printing and optimized job preparation and postpress processes. A Heidelberg Speedmaster XL 105 10-color perfecting press with coating unit is currently used for printing.

Supply on Demand helps pharmaceutical customers reduce their total cost of ownership. The precision delivery of the required quantities reduces storage costs or eliminates them completely in case of direct delivery to the packaging machine. That helps to avoid costs for destroying obsolete packaging. The close IT integration saves administrative costs as well.

In the quality process, Rondo can handle the customer's incoming goods inspection in compliance with strict GMP regulations. It’s reported that these advantages can save up to 50% of a customer’s total supply chain costs. Shorter packaging delivery times also enable the pharmaceutical customer to reduce delivery times for their medicines, yielding sales benefits.

“We stand for customized developments and for innovations,” says Hans-Peter Süßlack, Rondo’s Business Process Manager. “Offset printing has its limits when it comes to the personalization and run lengths of just one pack. That's why we took a serious look at digital printing. We tested quite a few systems in the past four years. We saw the Primefire 106 at drupa 2016 and opted for this machine after various tests.”

The Primefire 106 is said to be the first industrial digital printing press for packaging in B1 format, complementing the Speedmaster in 70 x 100 format.

Serial numbers and anti-counterfeiting

Beyond its economical production of batch-size quantities of pharmaceutical packaging, the Primefire 106 is also capable of adding variable data such as serial numbers during package printing. “A decisive factor in addition to the right format is the long-standing, reliable and trusting partnership with Heidelberg,” adds Jörg Oswald, Rondo’s Director of Operations. “A stable customer/supplier relationship with a high degree of trust and a high quality standard is very important in the pharmaceutical industry. The motto is safety, safety, and once again safety.”

With this in mind, a development project for the Primefire 106 consists of printing custom serial numbers in order to prevent counterfeit medicines under the EU Counterfeiting Directive. This subproject should become reality in 2019.

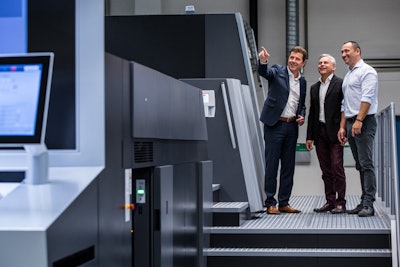

The Primefire 106 is installed next to the Speedmaster XL 105 in Rondo AG's production hall. “Both systems complement each other's respective strengths, which in turn benefits the customer. The Primefire 106 handles shorter runs and jobs involving variable data, while the Speedmaster XL 105 is perfect for longer runs,” points out Giovanni De Luca, Director Operations for Switzerland at Rondo. “Heidelberg's extensive color expertise ensures that end customers cannot see any difference—a must in the pharmaceutical industry.”

Rondo AG production is completed in Switzerland, the Czech Republic, the U.S. and Puerto Rico. Rondo is part of Medipak Systems, the pharmaceutical systems division of the international technology group Körber.