This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Solvay Diofan® Ultra736 polyvinylidene chloride (PVDC) coating solution has an ultra-high water vapor barrier that allows carbon footprint reduction for pharmaceutical blister films. As an aqueous dispersion, Diofan® Ultra736 meets regulatory requirements for direct pharmaceutical contact and supports the design of sustainable films with thinner coating designs.

The PVDC coating was custom-engineered to maximize the water vapor barrier without sacrificing its high oxygen barrier, chemical resistance, or transparency. The product also exhibits excellent thermoformability, enabling smaller pack sizes with higher pill density, compared to incumbent alternative coating solutions.

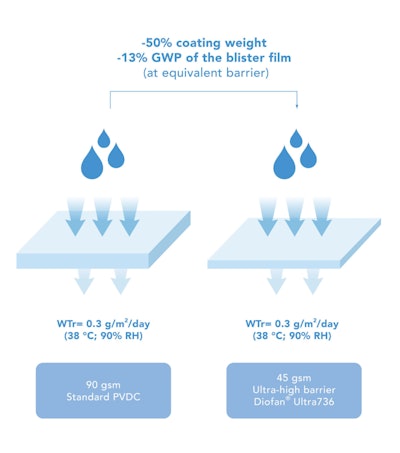

Due to its ultra-high barrier performance, Diofan® Ultra736 allows the reduction of the coating thickness, compared to incumbent mid- to high-barrier PVDC coatings, without impacting its functionality. In particular, it has been shown that, for Duplex barrier structures, Diofan® Ultra736 enables halving the number of base coat layers while delivering the same water vapor barrier. This approach can contribute to decreasing the overall carbon footprint of final blister film structures by up to 13%.

“Consumers and legislators are requesting increased efforts related to carbon footprint reduction from the packaging industry, and one of the most effective means to this end is to reduce the size and weight of packaging products,” says Federico Baruffi, global marketing manager, Packaging, Solvay Specialty Polymers. “Our new Diofan® Ultra736 coating solution can help packaging film manufacturers achieve superior barrier properties with thinner structures, leading to a significant carbon footprint reduction of the blister film.”