Spotted atHealthcare Packaging EXPO Booth #W-703, Weiler Labeling Systems (WLS), a ProMach product brand, is displaying the new LP-100R on-demand label printer. Printer applications include printing variable data on pre-printed labels and on-demand printing the entire label from “bright stock,” as needed.

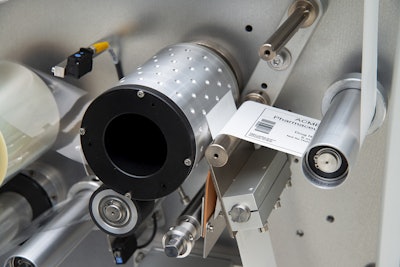

Antares Vision’s new Total Layout Control (TLC) vision inspection system for narrow webs is making its global debut on WLS’ LP-100R. Designed specifically for the LP-100R, the narrow web TLC, which is comprised of a line-scan camera, computer, HMI and software, is capable of whole-label inspection, including image matching, code reading and color verification.

The CE-marked and UL-certified LP-100R is designed for manufacturers and contract packagers of over-the-counter (OTC) and regulated pharmaceuticals, nutraceuticals, diagnostics, medical devices, biotech products and more.

Delivering digital flexibility, the stand-alone high-speed LP-100R eliminates the need to inventory distinct labels for each product while its high resolution and print wear resistance on a wide variety of substrates helps to maximize label quality and permanence.

The LP-100R is an extension of the company’s LP-100 prototype, which they brought to PACK EXPO last year with favorable feedback. After extensive market research to determine the desired capabilities, the LP-100R was born.

Featuring a UV-curing, drop-on-demand (DOD) printer, the LP-100R can print linear barcodes, serialized 2D data matrix barcodes and human readable codes as well as high-impact visual graphics in full color or black-and-white at speeds up to 4,700 inches per minute.

Interoperability

When combined with an appropriate vision inspection system and WLS’ optional ‘reconciler,’ the LP-100R will automatically remove any out-of-tolerance labels from the label roll. WLS can equip the LP-100R with no vision system or virtually any standard or customer-specified vision system for inspecting variable data. For whole-label printing applications, a specialized new whole-label vision inspection system was developed.

The LP-100R can handle a label roll size up to 18 inches (457 mm) in diameter with a 3-inch (76-mm) diameter core. Featuring balcony-style construction and an integrated electrical enclosure, this compact label printer is designed to meet the requirements of pharmaceutical and medical device manufacturers.

Print changes are quickly made via recipe downloads on the color touchscreen HMI. Label styles can be changed in less than five minutes with no tools required and no change parts. Low level, end-of-web and broken web detection can be programmed to flash a light and/or send an alarm to operators. The HMI is password protected with multiple levels of access to help secure the operation. Equipped with Ethernet ports, the LP-100R can be connected to plant-wide networks to share data for reporting purposes and enable remote diagnostics.

Like the stand-alone LP-100R, the new LP-100L features the same printing, vision and reconciliation capabilities. Unlike the LP-100R, which rewinds the printed labels onto a roll for off-line printing, the LP-100L feeds printed labels directly to virtually anylabelingmachine.

WLS provides inks for their LP-100 printers and supports customers in identifying the appropriate substrate for their needs.Achieving superior print quality and print wear resistance on most substrates without the need for a protective top coat, the LP-100R is capable of producing the highest graded codes.