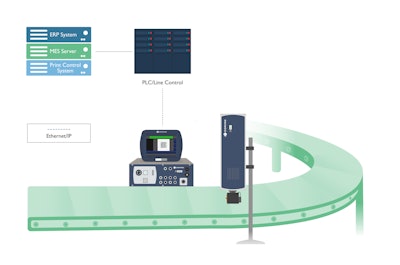

Formatted for its D-series and F-series lasers, Domino’s hardware device provides direct communication from the coders to the PLC (Programmable Logic Controller). Utilizing their existing line equipment, Domino customers will have full control over their laser coding and marking equipment, and its messaging, through standard industrial protocol. The coder can also relay performance data, allowing for predictability and pre-emptive maintenance.

Designed to be easy to configure, the EtherNet/IP is “plug and play,” and does not require extra programming—only four clicks are needed to connect the Domino printer to the hardware. Its connection to a single board computer allows for standard PLC tags to be sent to the printer. Statistics on printer performance can also be seen in real time, allowing for rapid issue diagnosis and data interpretation.

Other data transfer system setups may consist of additional programming in order for the printer to communicate with the PLC—the various functions that enable the connection, which are generally limited and inflexible, have to be coded, which requires technical expertise. These technologies may necessitate extra equipment and external software or may involve third parties. This can delay issue diagnosis or data feedback, and with highly complex systems, costs may be incurred due to ongoing engineer training.

The transferring of data from the laser to customer PLCs is a key issue in Industry 4.0 technology because knowledge of the laser performance is essential for the smooth running of high-speed industrial automation applications. Whenever a malfunction occurs on the line, high-speed control services must identify and send this information promptly to operators, so any problems can be rectified as soon as possible.

EtherNet/IP gives customers a central hub from which they will have comprehensive access to their network, giving them full control of the printers and avoiding the need to configure each individual machine. Direct messages can be sent in real time to laser printers from one device, requiring no additional scanning or processor usage. EtherNet/IP works fast, making it ideal for time-critical applications. This hardware extends the customer’s ability to record printer data, statistics and other information from the plant line without any additional equipment or external involvement, removing delivery delays and limited or inflexible functions.

The newly introduced technology is validated by ODVA, the managing association of EtherNet/IP. It performs as an integrated part of the PLC, reaffirming its reliability and functionality. Users of the technology will have direct access to their network, giving them full control of the printers from one central controller and avoiding the need to configure each individual machine.

The Domino printer is connected to the customer’s system without any add-on accessories, keeping the entire platform simple to run. Diagnostics and troubleshooting can be quickly and easily identified.