This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

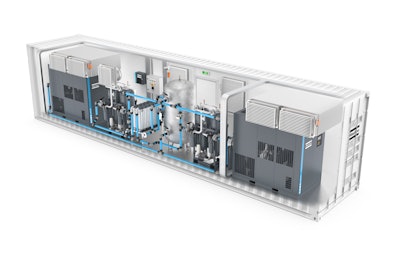

The Atlas Copco Aircube plug-and-play compressor room delivers containerized compressed air facilities when and where they are needed, saving space in production facilities or eliminating having to wait for new buildings to be constructed, allowing businesses to ramp up their output quickly. Because the applications for compressed air containers are too diverse for a one-size-fits-all solution, the Aircube enables companies to select their own plug-and-play configuration by choosing from a wide variety of compressed air equipment and many different options.

An Aircube can be equipped with fixed-speed or energy-efficient variable speed drive compressor(s) with sizes ranging from 15 to 110 hp, depending on the models chosen. Customers can then add the dryers, air receivers, filters, and any special add-ons that best meet their needs. Atlas Copco will assemble all of these products in a 20- or 40-ft ISO-certified sea container. The result being all components of an Aircube containerized compressor room have already been certified, thoroughly tested, and made to work together.

“The Aircube concept is a truly great option for our industrial customers,” says Trey Ragsdale, business line manager for industrial air products in the United States for Atlas Copco. “We are offering companies a top-quality, containerized compressor room that is tailored to their needs— the result is a true plug-and-play solution that provides operators with unrivaled flexibility, quality, reliability, and efficiency.”

The Aircube comes with a number of standard features, such as ventilation, internal power distribution, certification, and lighting. A wide array of options is available, including environmental add-ons, smart connectivity and control features, ISO 8573 filtration class options, and safety add-ons. The Aircube container is built to withstand temperatures from 32 °F to 110 °F. Containers that can operate in low temperatures (-40°F) are available as an option. Containers that can work in even higher or lower temperatures or very high ambient conditions (-58°F to 120°F) can be supplied on demand.