This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

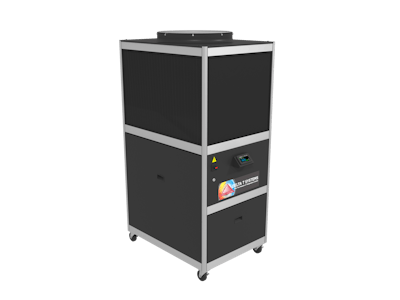

Delta T Systems has announced that its entire chiller product line can now be equipped with variable frequency drives (VFDs) to control the pump motor.

A variable frequency drive (VFD) is a device used to manage all actuation states of an electric pump motor. This is accomplished by varying the frequency and voltage of the power supplied to the motor. VFDs are widely used to provide soft motor starts, speed ramp-ups, and steady operating speeds, as well as ramp-downs and stops.

Even though drives control the frequency and voltage of the power supplied to motors, they are often referred to as speed controls, since the result of power and frequency changes is an adjustment of motor speed.

There are important benefits to the use of VFDs:

● Greatly reduce or eliminate shock induced mechanical stress and failure. VFDs allow motor/pump unit soft starts that reduce stress on both piping and system components.

● Significantly cut electrical power consumption—often by up to 50%

● Reduce maintenance/operating costs.

The primary reasons for adjusting the motor speed on chillers is to control process variables. VFDs on Delta T Systems process pumps are used to control one of the following:

1. Delivery Flowrate: The VFD controls the desired flow rate set by the user.

2. Delivery Water Pressure: The VFD will control to the desired chiller delivery pressure set by the user.

3. Remote Pressure: The VFD will control pressure based on input from a remote process sensor. This sensor can be supplied by Delta T Systems and may be mounted anywhere in the process where pressure is best measured.

4. Manual Control: The VFD can be manually set by the user.

All of the process parameters can be set directly by user input on the chiller HMI or remotely through one of a variety of communication protocols.

The Delta T Systems VFDs also have several parameters that can be adjusted to tune them to unique customer’s process characteristics.

As a leader in the development of process temperature control equipment, Delta T Systems is proud to include the VFD technology to industrial process chiller systems. In addition to contributing to significant efficiency improvements and operating cost reductions, being a supplier of green technology is both a source of pride and a fulfillment of its belief in corporate environmental stewardship responsibilities.