This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

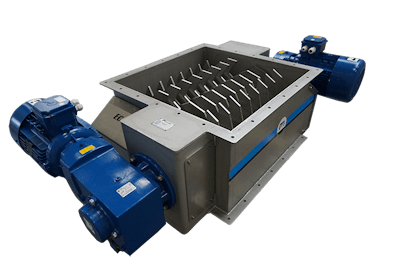

Palamatic Process lump breakers promote the free flow of dry materials that tend to form agglomerates in storage or when exposed to humid conditions. Supplied in mild, 304, or 316 steel, the lump breakers utilize two pin shafts with knives or blades that spin at a fixed or variable rate. A stationary mesh screen below the grinding medium helps increase the efficacy of the de-lumping mechanism. The lump breakers are available with bulk bag discharge stations and fine powder milling equipment; modifications can be made to meet different hazardous area classifications.