This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

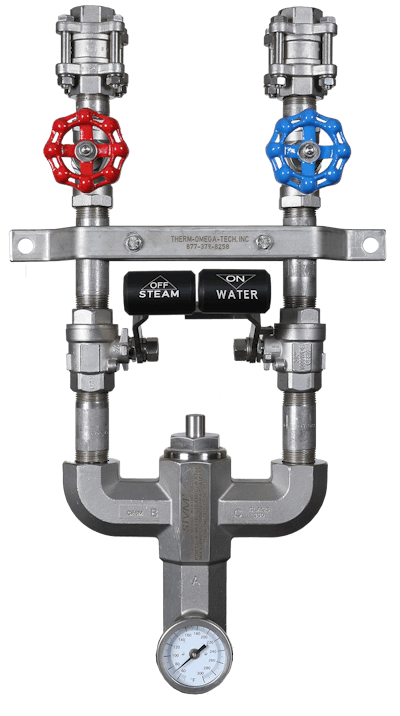

Utilizing a self-scouring, silent Venturi mixing valve to combine steam and water, the ThermOmegaTech washdown station delivers high-temperature washes at user-defined temperatures. The STVM washdown station includes a mixing valve that reduces flow if the output temperature exceeds the factory setpoint and completely stops flow 15 °F above it. Interlocking steam and water shut-off ball valves shut off both inlets at the same time to prevent accidental steam-only, “hose full of steam” operation. Incorporating a cartridge that can be removed with a standard wrench and cleaned in a descaling solution before reassembly, the station is in-line serviceable.