This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Three packaging lines, including one with an upstream tablet press –

Romaco will take advantage of the upcoming Achema to demonstrate its

expertise when it comes to configuring turnkey concepts. The

manufacturer will also show a whole series of standalone units for

pharmaceutical production and packaging.

Romaco Unity 500 in line with the Promatic PTT and the Promatic PAK 130

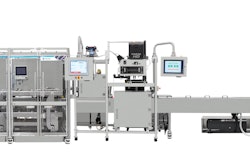

Romaco’s new Unity 500 blister packaging line is set to make its public debut at

Achema 2018. This monobloc machine will be on show in line with the Promatic

PTT for seamless track & trace and the new Promatic PAK 130 case packer.

Romaco specialises in single-source turnkey concepts – with the primary,

secondary and final packaging all in one line. A compact, GMP compliant design

was a key priority for the fully integrated blister packaging line. With a maximum

output of 500 blisters and 150 cartons per minute, the Romaco Unity 500 is

mainly intended for high-performance jobs at medium speeds.

For the first time ever, the Romaco Unity 500 will be teamed up in Frankfurt with

a Combo v2.0 feeder from Elizabeth Europe. This patented system gives

Romaco increased flexibility for feeding pharmaceutical solids in numerous

different shapes and sizes. The finished blisters are passed directly to the

cartoner’s bucket chain by means of a vacuum assisted overhead conveyor and

QuickTransfer, which works according to the positive transfer principle. Separate

servo drives ensure safe operation at the individual stations. Apart from an

advanced level of automation, the Romaco Unity 500 also offers excellent

opportunities for improving overall equipment effectiveness (OEE). The optimal

access to all components speeds up and simplifies cleaning of the blister line.

The fast product changes add up to significantly less downtime for the Romaco Unity 500. Reproducible format parameters and QuickAdjust, the automatic

station control system, simultaneously reduce the run-in times to almost zero.

Innovative final packaging solutions with track & trace function.

The Promatic PTT, which can be flexibly connected to any standard cartoner,

checkweigher or transfer system, was developed by Romaco to enable tamperevident

identification of cartons. This new track & trace machine provides

numerous functions for seamless monitoring all along the supply chain, for

example the cartons can be laser or inkjet printed with 2D Data Matrix or QR

codes. The data can then be read out using OCR/OCV. The packs can

additionally be closed with various seals or labels for even better protection

against counterfeiting. A vignette applied to the top of the carton provides further

proof of originality. An interface to special serialisation software rounds off the

Romaco Promatic PTT.

The Promatic PAK 130, too, is shipped ready for integrating aggregation and

serialisation solutions. Up to five shipping cases per minute can be filled with this

semi-automatic machine. Romaco will show the compact Promatic PAK 130 at

Achema in line with the Romaco Unity 500 and the Promatic PTT.

Romaco Macofar LF 202 liquid filler with the Promatic PC 4000

A Macofar LF 202 attached to a Promatic PC 4000 continuous motion cartoner

will be another highlight at the upcoming trade fair. This latest member of

Romaco’s Macofar LF product family was likewise designed for processing nonsterile

liquids and is ideal for filling not only pharmaceuticals and cosmetics but

also nutraceuticals. To meet the requirements of such diverse applications, the

Macofar LF 202 can be equipped with various filling, check and closure systems.

The version with a table top design has two closing stations to enable dosing

caps to be fitted to bottle screw caps, for instance.

With a maximum output of 12,000 bottles per hour, the Macofar LF 202 is up

among the leading performers at high speeds. The actual production speed

always depends on the bottle size and the filling volume, which ranges from 0.5

to 500 millilitres. Versatile technology is a must here. The positive bottle handling

principle and the positive transfer of the stoppers and caps by means of pick &

place guarantee a highly reliable process whatever the application. If necessary,

the Macofar LF 202 can also be equipped with laminar flow or supplied in an

ATEX version.

The filled and stoppered bottles are transferred to Romaco’s Promatic PC 4000

continuous motion cartoner and packed in cartons at a maximum speed of 250

units per minute. In addition to the obligatory leaflet, various medical devices

such as spoons or pipettes can be inserted depending on the customer’s

requirements.

Integrated line for tableting and packing dishwasher tabs

Romaco Kilian and Theegarten-Pactec will join forces to show an integrated

solution for tableting and packing triple-layer dishwasher tabs together with an

AZO powder feeding system. The powerful Kilian KTS 1000 is tailor made for

processing corrosive, abrasive or acidic products. The dishwasher tabs are

transferred to the Theegarten-Pactec FPC5 and wrapped in flow packs with a

maximum output of 1500 tablets per minute. In addition to numerous industrial

applications, the Kilian KTS 1000 is also ideal for the food and cosmetics

segments.

The extra-robust KTS 1000 tablet press is offered in three different configurations.

The 3L model for compressing triple-layer tablets is shipped by Kilian with three

fill shoes and four compression stations. The tablet press achieves compression

forces of up to 120 kN with a pitch circle of 840 mm. Targeted measures reduce

in-process vibration to a minimum. The patented, wear-free punch brake

magnets and hydraulic overpressure protection enable an even more reliable

process. Thanks to its dedicated tooling and optimised product feeding system,

the Kilian KTS 1000 compresses even sticky or poorly flowing powders efficiently.

Other highlights at the Romaco booth

Apart from these line configurations, Romaco will also show several technologies

for packing, tableting, granulation, coating and drying pharmaceuticals. A Siebler

HM 1-230 strip packaging machine, tablet presses in the Kilian KTP, KTS, K and

STYL’ONE Evolution series and Innojet VENTILUS® processing machines will

provide an impressive demonstration of the Romaco portfolio’s diversity.

Romaco’s newest service products will round off the engineering specialist’s

trade fair exhibit.

Blister formats from Romaco Noack can be created quickly and easily using the

new BlisterMagic software. The system checks automatically whether the desired

formats are feasible based on the product specifications. PartGuard, developed

by Romaco Kilian, will in future be responsible for procuring and managing spare

and wearing parts. This innovative warehouse system keeps a continuous watch

on the customer’s inventory levels and makes sure owners of Romaco-built

equipment have all essential spares in stock in the right quantity exactly when

they are needed. Last but not least, Romaco will present the latest generation of

its smart glasses.

On show at ACHEMA in Frankfurt/Main (Germany) from June 11 to 15, 2018

(Messe Frankfurt, Hall 3.0, Stand B49).