This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The Gerhard Schubert GmbH is considered a true pioneer in packaging machine engineering in Germany. Established in 1966, the company quickly grew into an acknowledged leader in digital packaging machines. Today, led by the family’s second generation, Schubert employs close to 1,100 people. And to this day, the company has kept its pioneering spirit: Schubert regularly surprises the market with new technologies and automation solutions, setting new standards in the industry again and again. This year, Schubert is celebrating the foundation of the company exactly 50 years ago.

The Schubert success story began in the 1960s with the concept of building a packaging machine using standard components. In 1966, to implement his idea, Gerhard Schubert founded the Gerhard Schubert GmbH and began construction of the first carton erecting and gluing machine (SKA), with which the Weiss company in Nuremberg packaged its world-famous gingerbread “Lebkuchen”. Within just a few years, the entrepreneur developed the first SSB modular machine (Schubert-Sondermaschinen-Baukasten) for filling and sealing cartons via top loading. With these developments, Gerhard Schubert paved the way for the world’s most flexible packaging machines.

In the 1970s, the Crailsheim-born Gerhard Schubert was already considering how he could use robotics to maximise the flexibility and adaptability of packaging operations. The basic idea behind his vision was really quite simple: human nature would serve as the perfect model for his packaging machines. “I wanted to develop a machine built according to human principles: simple mechanics, a high level of intelligence and the use of tools. This was the platform upon which we manufactured our machines.” In 1981, at the Interpack fair, Schubert presented the world’s first-ever packaging robot to package chocolates: “ROBY”. A major breakthrough with robot-based packaging machines followed with the development of the SNC-F2 pick & place robot which celebrated its premiere at the 1987 Interpack fair.

At the same event, Schubert presented its first chocolate packaging line: the Schubert Speedline, equipped with the first Schubert robot for optical image recognition. Schubert brought experts in optical image processing into the company in view of developing an in-house R&D department. Since then, the company has ranked among the pioneers in this key area, and just recently reached a new milestone with its market-ready 3D scanner.

Artificial intelligence and networked production

Gerhard Schubert saw the long-term success of packaging robots as being mainly based on balancing more control with less mechanical components. And since he believed that there weren’t any control systems on the market in the 1990s to meet the specific requirements of packaging machine engineering, he developed his own. In 1996, the company introduced the first machine with an intelligent control system to the market. The VMS packaging machine control system set the stage for a simple machine structure with a reduced number of mechanical components, which led to the development of today's modular sub-machines.

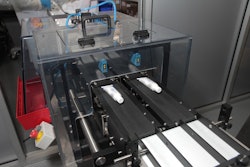

Today, the seven basic modules enable a highly adaptable machine structure, within which all functions, such as feeding, erecting, filling, capping/lidding/sealing, labelling, marking and palletising can be combined. In addition to the VMS control system, two-, three- and four-axis robots, as well as image recognition systems and the recently introduced standard-component “Transmodul” transport robot, all come together to form the Schubert’s current Top-Loading machines (TLM). Thanks to these rail-based robots, transport tasks can be engineered much more efficiently. At the same time, the Transmodul further increases the compactness of the TLM systems.

“Our goal is to combine intelligent software and reduced mechanics, while continuously increasing flexibility and adaptability,” explains Ralf Schubert, who has been running the Schubert business since 2012 together with his father Gerhard, his brother Gerald Schubert and Peter Gabriel. Based on this principle, Schubert presented the first packaging machine without an electrical cabinet at the 2014 Interpack fair. The innovation sets a new benchmark in system efficiency and availability. “We still see ourselves as a pioneer in packaging machine engineering and we will continue to set standards in the industry. This year, the sector can once again look forward to cutting-edge innovations from our company,” confirms Gerald Schubert.

Schubert also has ambitious objectives for the future. By the year 2020, the company intends to increase its yearly volume of manufactured sub-machines from its current 650 to 1,000 units. Schubert is also striving to significantly shorten delivery times over the next few years. “In the future, our vision is to build a machine in just a few hours,” says Ralf Schubert. With this in mind, the graduate computer scientist is currently driving the development of a “digital twin”, whereby future TLM machines can be simulated early on via a 3D model, which will greatly reduce the time required through to commissioning of the real machine. Over the next few years, delivery times will be more than halved.