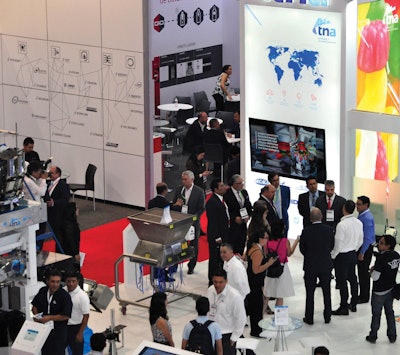

EXPO PACK México 2018 (Expo Santa Fe Mexico, Mexico City, June 5-8) revealed a more complex, more mature market in Mexico and Latin America than existed when the event started 32 years ago. It’s different now than it was even five years ago.

What used to be considered a good show for the high-volume, low-cost, or entry-level machinery that developing markets require now supports a heathy demand for a plurality of machinery sophistication, including the fastest and most innovative.

In Mexico in particular, the beverage industry continues to set the pace among categories in new investment, with new breweries making beer the largest subsector. The biggest brewery in the world is coming soon to Mexico. Heineken, AB InBev, and Constellations Brands alone project 15 million hectoliters in new capacity in 2018. Such installations aren’t going to be using entry-level machinery.

And in the broader Latin American market, consider the growth of snack food. According to the “2018 Snack Foods Packaging and Processing Market Assessment and Trends” study from PMMI’s Business Intelligence (access a free executive summary at pwgo.to/3546), developing countries in Latin America and Asia Pacific will continue to grow at the fastest global rate, with larger Europe and North America remaining comparatively flat. This growth requires automation, and the region already has at least 32 years of installed base to grow upon.

None of this is to say the entry-level market isn’t still a vibrant portion of this regional packaging machinery scene. Bosch Packaging Machinery, for instance, a producer of some of the most sophisticated machinery around the globe, used EXPO PACK México 2018 to help roll out the entry-level Pack 102, a hygienic, stainless steel horizontal flow wrapper at a price point that’s well-suited for developing markets.

But on the other side of the coin, Serac had its FC filler/capper machine on-site at the show. The machine aims for extreme precision in its fill, and while many machines aim at a three-sigma precision limit, this machine attains one-sigma. Now, this level of precision might not be necessary if the overfill were an inexpensive liquid, like water. But for expensive products, like motor oil, perfume, milk, or anything else that has a lot of processing tied up in it prior to reaching the filler/capper, that’s a different story.

“We pride ourselves on this precision, and a lot of times return on investment can be less than a year just by product giveaway savings,” says Alan Bonanno, Marketing Manager, Serac Group. “And that doesn’t just apply to the North American or European market, that applies here, too. If we can save an end user one or two grams per bottle, and they’re doing 300 containers a minute, that adds up wherever you are.”

Meanwhile, PolyPack brought to the show a top-of-the-line shrink-bundling machine, capable of speeds of 60 bundles/min for this application, that it would otherwise market to Coca-Cola Co. or other massive players the world over. But this several-hundred-thousand-dollar machine has already been sold into the Mexican market for a milk application with Sello Rojo, Guadalajara. What’s more, the machine is being added to an existing Tetra Pak line, no small piece of innovation for no small price in its own right.

“So if I were to tell most people, ‘I’m going sell a $300,000 bundler in Mexico,’ they’d likely say, ‘No, you’re going to sell a $30,000 bundler,’” says Emmanuel Cerf, VP of Sales and Marketing. “But this is a machine that is state of-the-art, and we’re selling it here because the region is growing, and they need the capacity, and they need the speed, and they can’t really do it manually or semi-automatically at those speeds.”

And this wasn’t a freak occurrence. PolyPack has had a number of large installations in Mexico and Latin America.

“We have to look at Mexico as a developed market,” Cerf says. “It’s not a new market, it has been established. We’ve been here for 20 years now, and we’re now seeing some really nice facilities. They’re right up with Europe and North America.”

Elswhere, Nalbach Engineering Co. used the occasion to demonstrate a higher price-point multilane auger filling system that uses direct-drive servo systems on its hoppers instead of clutch-brake controls. These are just a few examples, but the list of exhibiting OEMs targeting sophisticated end users was exhaustive.

More maturing trends

Cost is no longer the lone market force in Latin America, as the invisible hand of consumer demand drags brands and manufacturers into new sustainable, ecological, and package design territory.

In a region known for churning out produce in all seasons, the organic, clean label trend is really hitting its stride in Latin American markets.

“In my experience, and I’ve been coming here for 25 years, Mexico has not been particularly fast in adopting recycling, less-is-more, reusable packaging trends, probably similar to how the U.S. has been slow compared to Europe,” says Dennis Quinn, Sales Coordinator, Foremost Fuji. “They’re just like us. These sorts of green initiatives weren’t important until there was a benefit for someone. Now, there’s a cost savings to source reduction, and there’s a necessity of meeting a customer demand for green packaging where there wasn’t one before. Just like us in the U.S., there has to be a reason, other than it simply being the right thing to do, to address these trends. There has to be an economic reason, and reduction of materials was an obvious one. Plus, brands are now being pushed by the Latin American consumer to have a better package for the product. If we can produce a better package, the product will sell better, so it’s more cost effective to use better packaging. Until recently, packaging was all cost-related, but now there’s a market demand to do better.”

Cerf agrees, saying that this year was the year of the so-called “Eco Project.” Outwardly, the “Eco” refers to ecology, but realistically, it refers to economy, too.

“We have many more projects going on right now in Mexico and Latin America that they call ‘Eco Projects,’” says Cerf. “They want to save both the environment and save money doing it. By reducing consumables, they can accomplish both.”

EXPO PACK México by the numbers

EXPO PACK México 2018 closed as the largest event in the show’s 32-year history, with more than 23,000 attendees. The event featured 1,000 exhibitors occupying more than 19,700 net square meters (212,000 net square feet) of Expo Santa Fe. The PMMI Pavilion also set a new standard with 100-member companies across 2,950 net square meters, 18% larger than the 2016 Mexico City show.

“Attendees have come to expect innovation and the latest technology from EXPO PACK México, and it continues to exceed all of our admittedly high expectations,” says Jim Pittas, PMMI president and CEO.

GRUMA, headquartered in San Pedro, Mexico, is the largest manufacturer of tortillas in the world and makes sure to send a full buying contingent to both EXPO PACK México and EXPO PACK Guadalajara.

“EXPO PACK México not only allows us to see what is new and innovative but, as a regular visitor, we have established relationships with exhibitors that we now do business with,” says GRUMA’s Juan Enrique Rollas, Maintenance and Packaging Manager.