Sometimes a Consumer Packaged Goods company finds an emerging trend in packaging so appealing that management refuses to wait for the supplier community to fully develop the technologies that will make it possible to capitalize on that trend. One such company is Philip Morris International (PMI), whose corporate headquarters are in New York City and whose Operation Center is in Lausanne, Switzerland. The trend they spotted is digital printing and finishing of folding cartons, and now that they’ve spotted it, they’re going after it as aggressively as any brand owner on the planet.

“The question is ‘when’ not ‘if’ digital printing will take an increasing share of the total volume,” says Tony Snyder, Vice President Product Portfolio Management and Deployment at PMI. “Brand owners need to decide if they will sit back and wait for the advances still needed to make it economically attractive, dip their toe in the water, or dive in head first. The choices we make will determine if digital becomes just another option we call on or if it becomes the disruptive catalyst to a fundamental change in the business model of today.”

Snyder and company have decided that there will be no dipping of toes where digital printing and finishing of folding cartons is concerned. It’s head first all the way. Snyder puts it this way: “Why sit patiently and wait ten years for what we need to be ready when we can push things forward by putting some skin in the game?”

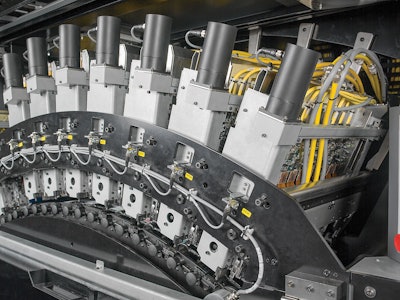

And so it was that in 2017 PMI installed in its Neuchatel Innovation Development Center a Gallus Labelfire 340, a hybrid press that combines the latest digital printing technology with the benefits of conventional printing and further finishing technology. Jointly developed by Gallus and Heidelberg, this inline label printing system features a printing module with SAMBA ink-jet printing heads developed by Fujifilm Dimatix and Fujifilm Corp. SAMBA drop-on-demand inkjet printheads utilize Dimatix’ proprietary Silicon MicroElectroMechanicalSystems (Si-MEMS) fabrication methods combined with VersaDrop multi-pulsing jetting capability. Collectively, these technologies and other innovations enable printhead nozzles to be arranged in a matrix array that, says Fujifilm, provides unparalleled stability, uniformity, maintainability, and scalability in a compact package. Described by Fujifilm as a “breakthrough in print head design,” the SAMBA print heads combine the packing density and cost of Thermal Ink Jet (TIJ) with the high throughput of Continuous Ink Jet (CIJ) while offering the operational flexibility associated with Piezo Ink Jet (PIJ).

Getting back to PMI, Snyder says there are the two key drivers responsible for digital printing’s appeal: the consumer’s thirst for differentiation and the need of today’s CPG companies to keep inventories of packaging materials to a minimum. After all, digital printing is a process that does away with any need for printing plates or tooling, which makes it economically suitable for short runs that keep inventory in check and for quick changeover capabilities that make it possible to differentiate packs on shelf.

But there’s a third driver behind PMI’s digital journey: IQOS (I Quit Ordinary Smoking). This battery-powered tobacco heating system is the foundation of the firm’s vision of a Smoke-Free Future, a vision aimed at bringing about a profound transformation of PMI. The idea is to use the IQOS device to heat tobacco to no more than 350º C, which is warm enough to release nicotine to the user but not warm enough to burn the tobacco.

“The heat-not-burn idea recognizes that the most harmful part of tobacco use is the smoke,” says Snyder. “By eliminating the smoke, you have a significant reduction in the levels of toxicants that are considered harmful or potentially harmful, a reduction that’s in the range of 90 to 95%. So it’s a way of saying that if somebody is not going to quit tobacco, then it’s better they have an alternative that is potentially less harmful than a cigarette.”

‘Radically different portfolio’

According to Snyder, IQOS—widely available around the world but not yet approved for sale in the U.S.—makes digital printing all the more compelling. “I think digital’s time has come even without factoring in IQOS,” says Snyder. “But when you do include IQOS in the conversation, it means we’re going into a radically different portfolio. With these reduced-risk products you’re not just looking at the consumable tobacco heatsticks. In addition to the battery-powered device itself there are cables, chargers, replacement parts, user guides, safety documentation, and so on. As we thought about the packaging for such a portfolio, we knew it required a new mindset, especially when we were launching a portfolio of products in 43 markets in the last 24 months. You can do all the planning and forecasting you want, but you don’t know which varieties are going to resonate and which ones won’t. So the chances are that whatever volume of printed materials you order into a conventional supply chain driven by analog equipment, it’s going to be wrong. It’s either too little or too much. The speed and agility of digital allows you to be much more responsive and accurate. It’s the sweet spot for digital.”

It was this scenario that caused PMI to begin its digital journey about three years ago. What the development team quickly realized, says Snyder, was that “Digital wasn’t ready for us even if we were ready for digital. It had been driven largely by the wish to personalize. It was about niches. But we’re not a niche business, we’re a volume business, where ‘small’ volume is still counted in the millions of packs.

“Also, if you take a look at the cartons in our particular business, there’s a lot going on, from metallics to embossing to lacquers and right on into creasing and die-cutting. So we could see from the start that we would never realize the full value of going digital if we didn’t make the whole thing digital, including not just printing but also embellishment and finishing. Of course, that simply wasn’t available three or four years ago, though we believe in time it will be. But rather than wait, we installed what was available, namely a hybrid system that is absolutely modular, a system with a digital press that has extended color gamut that lets us print eight colors at 50 meters/min. Embellishing, cold-foiling, embossing, and other finishing operations on the Labelfire 340 are still analog, but as digital solutions become available we’ll plug them into this highly modular line.” As for creasing and die cutting, while it’s not yet an inline process, it can be done digitally in the Neuchatel development center on a Lang Laser system.

PMI’s choice of the Labelfire 340 is an interesting one in that, as its name suggests, the machine was really designed for printing of labels. But according to Christian Marxer, Manager of Printing Technology at PMI, it was the Labelfire that was commercially available when PMI was ready to make its move. It had the required hybrid capabilities plus the speed and print quality that was needed, and its modular nature will make it easy for PMI to incorporate additional digital stations in place of analog operations currently in place.

Marxer says that Gallus needed to make a few adjustments before the Labelfire 340 was ready to be used for carton stock. Web tension is considerably higher for PMI’s standard paperboard, so transport and guiding systems needed to be reinforced. Rollers, too, needed to be modified in order to handle the heavier paperboard. As for the UV-cured inks, Heidelberg developed these, too.

What digital brings

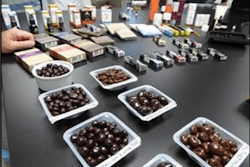

As configured for PMI, the Labelfire consists of two flexographic stations, then the eight-color digital printing station, then four more flexo stations for coatings or lacquer or tactile embellishments, then an embossing station, and then rewind. For a concrete example of what PMI might do with digital printing in its arsenal, consider the multicolored bars in the Marlboro R3MIX package shown in photo above. This was a limited edition where consumers were offered different capsule flavor cigarettes within the same pack. This variability in product was extended to the pack design itself because, thanks to digital printing, 16 different pack varieties were printed in the same print run. What changed from pack to pack was the length of the colored bars. So when consumers faced multiple packs on shelf, they saw not one static image on every pack but rather a pleasantly surprising array of imagery that reflected the product variability inside each pack.

One modification scheduled to take place in Q1 of 2019 is the addition of a Digital Embellishment Unit (DEU), an innovation unveiled at Labelexpo 2017 by three Swiss companies. Steinemann supplied the basic technology based on its established dmax system for digital application of spot, full flood, varnish, or foil. Schmid Rhyner developed a UV-cured ink-jet effect varnish suitable for use with the dmax technology. And Gallus brought it all together by integrating it all on its Labelfire machine platform.

According to Andreia Fontes, Director of Printing and Converting at PMI, the DEU will occupy a position downstream from the digital printing station. Once it’s operational, PMI will be able to do in-line coating and apply matte, gloss, or tactile spot coating effects in various thicknesses—all digitally. Fontes sees it as another significant step in the firm’s ongoing quest to advance digital printing and finishing.

“Others who have an interest in digital see things becoming commercially available in five or ten years,” she points out. “But here, partly because we have this new product portfolio with IQOS, there’s a much greater sense of urgency. The conventional ways of working are just not going to cut it going forward. That’s why we decided not to wait, even though some pieces of the digital puzzle are not in place yet. We’ve failed a few times, but we’ve also learned a lot, and we are proud to say that we have successfully completed our concept validation. We know what is possible because we’ve done it.”

Snyder couldn’t agree more about redefining ways of working. “The Smoke-Free Future brings many operational challenges, but it also brings the opportunity to reinvent the way we work,” he says. “There’s still much to be done. We need to work on speed and ink prices, and on water-based ink options in addition to the UV-cured inks we now use. And of course we want to plug in digital processes in parts of the line that are currently analog. But that’s all part of the plan. What we didn’t want to do is wait. Technically speaking, this is a developmental operation as opposed to a true commercial converting line. But we’ve done real commercial packaging production on it, which is important, because I don’t think you can make real progress any other way. We want to show people that we are serious about the opportunity digital represents, and not just as an extra piece of printing technology that’s nice to have in the arsenal. We think this could be the new way of printing in large, commercial-scale volumes.”

Showing converters the way

Philip Morris enjoys a mutually beneficial relationship with the converters it relies on for the vast majority of its cartons. But thought leaders in the firm understand that there are times when waiting for the supplier community to develop the next big thing isn’t always the best idea.

“This is especially true for something like digital printing of folding cartons,” says Tony Snyder. Which is why the firm developed its own in-house hybrid digital folding carton printing and converting operation at its Neuchatel Innovation Development Center. This is not about vertical integration or self-manufacturing. The goal is to demonstrate to those on the supplier side just how keen PMI is about moving digital converting technology forward.

“We can’t do it ourselves,” says Snyder, who described PMI’s digital journey at Digital Print for Packaging Europe, produced by Smithers Pira. “We need to connect with the equipment makers, the converters who buy that equipment, and the makers of the inks and lacquers, too, and show them how strongly we believe there is a marketplace for these technologies. If you’re making digital converting equipment today, you don’t need to be persuaded to make it for flexibles or for corrugated, because the markets for those materials are pretty well defined. But if you don’t see customers pushing for the kind of digital equipment we need for our cartons, why would you spend your R&D dollars on digital carton printing and finishing equipment? That’s why we want to show people how keen we are to have such capabilities.”