“Personal Care Packaging” details the shifting trends disrupting the status quo. The market is being subjected to a lot of pack variations. With greater demand for multiple package sizes and packaging formats including tubes & pouches, aerosol cans, and PET/HDPE bottles, companies are facing challenges in terms of the need to speed up the changeover operation & maximize the output.

This not just affects primary packaging machinery, but also secondary packaging such as shrink wrapping machines. To remain competitive in the market, companies are required to be prepared with versatile machinery that can handle diverse shapes and formats.

“Now the growth of e-commerce is having an impact on the production line,” says Paula Feldman, Director of Business Intelligence for PMMI. “Selling a product directly to consumers and e-commerce vendors requires a different production line, including labeling, and to be successful in e-commerce a company has to increase its shipping rate.”

Machinery suppliers have been updating and providing solutions, but the pace of innovation remains slow, according to CPGs. The biggest improvement identified is in the usage of modular machines, allowing necessary flexibility and increased throughput.

“Acceptance of modular machines is good for big companies who can afford it,” says Feldman, “These modular machines can be moved to different production lines.” Smaller and mid-size manufacturers may still find the best solution with manual machinery that is easily cleaned and offers relatively short changeover times.

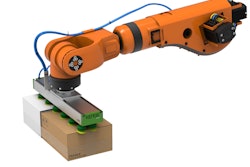

CPGs want innovations that eliminate or offer minimum human-machine interaction and deliver accurate automated product warehousing. With robotics and automation Personal Care CPGs can work with more fragile applications by eliminating human set-up errors, helping achieve higher product output while delivering the correct product/package mix.

But more technology means more complexity which sometimes can lead to higher costs and delays. Personal care product manufacturers expect machines which are easy to operate, require less maintenance, and include a common communications control platform.

With less skilled people available to run machines, packaging machinery OEMs will be expected to deliver maintenance services, says the white paper.

For more on machinery buying trends, regulatory compliance, safety and track and trace, download a FREE copy of the white paper here.

Source: PMMI Business Intelligence, “Personal Care Industry Trends.”

“Personal Care Packaging” details the shifting trends disrupting the status quo. The market is being subjected to a lot of pack variations. With greater demand for multiple package sizes and packaging formats including tubes & pouches, aerosol cans, and PET/HDPE bottles, companies are facing challenges in terms of the need to speed up the changeover operation & maximize the output.

This not just affects primary packaging machinery, but also secondary packaging such as shrink wrapping machines. To remain competitive in the market, companies are required to be prepared with versatile machinery that can handle diverse shapes and formats.

“Now the growth of e-commerce is having an impact on the production line,” says Paula Feldman, Director of Business Intelligence for PMMI. “Selling a product directly to consumers and e-commerce vendors requires a different production line, including labeling, and to be successful in e-commerce a company has to increase its shipping rate.”

Machinery suppliers have been updating and providing solutions, but the pace of innovation remains slow, according to CPGs. The biggest improvement identified is in the usage of modular machines, allowing necessary flexibility and increased throughput.

“Acceptance of modular machines is good for big companies who can afford it,” says Feldman, “These modular machines can be moved to different production lines.” Smaller and mid-size manufacturers may still find the best solution with manual machinery that is easily cleaned and offers relatively short changeover times.

CPGs want innovations that eliminate or offer minimum human-machine interaction and deliver accurate automated product warehousing. With robotics and automation Personal Care CPGs can work with more fragile applications by eliminating human set-up errors, helping achieve higher product output while delivering the correct product/package mix.

But more technology means more complexity which sometimes can lead to higher costs and delays. Personal care product manufacturers expect machines which are easy to operate, require less maintenance, and include a common communications control platform.

With less skilled people available to run machines, packaging machinery OEMs will be expected to deliver maintenance services, says the white paper.

For more on machinery buying trends, regulatory compliance, safety and track and trace, download a FREE copy of the white paper here.

Source: PMMI Business Intelligence, “Personal Care Industry Trends.”

“Personal Care Packaging” details the shifting trends disrupting the status quo. The market is being subjected to a lot of pack variations. With greater demand for multiple package sizes and packaging formats including tubes & pouches, aerosol cans, and PET/HDPE bottles, companies are facing challenges in terms of the need to speed up the changeover operation & maximize the output.

This not just affects primary packaging machinery, but also secondary packaging such as shrink wrapping machines. To remain competitive in the market, companies are required to be prepared with versatile machinery that can handle diverse shapes and formats.

“Now the growth of e-commerce is having an impact on the production line,” says Paula Feldman, Director of Business Intelligence for PMMI. “Selling a product directly to consumers and e-commerce vendors requires a different production line, including labeling, and to be successful in e-commerce a company has to increase its shipping rate.”

Machinery suppliers have been updating and providing solutions, but the pace of innovation remains slow, according to CPGs. The biggest improvement identified is in the usage of modular machines, allowing necessary flexibility and increased throughput.

“Acceptance of modular machines is good for big companies who can afford it,” says Feldman, “These modular machines can be moved to different production lines.” Smaller and mid-size manufacturers may still find the best solution with manual machinery that is easily cleaned and offers relatively short changeover times.

CPGs want innovations that eliminate or offer minimum human-machine interaction and deliver accurate automated product warehousing. With robotics and automation Personal Care CPGs can work with more fragile applications by eliminating human set-up errors, helping achieve higher product output while delivering the correct product/package mix.

But more technology means more complexity which sometimes can lead to higher costs and delays. Personal care product manufacturers expect machines which are easy to operate, require less maintenance, and include a common communications control platform.

With less skilled people available to run machines, packaging machinery OEMs will be expected to deliver maintenance services, says the white paper.

For more on machinery buying trends, regulatory compliance, safety and track and trace, download a FREE copy of the white paper here.

Source: PMMI Business Intelligence, “Personal Care Industry Trends.”