This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

TurboFil Packaging Machines LLC, an equipment specialist dedicated solely to the design and development of liquid filling and assembly machines, has developed an automatic version of its assembly and vial filling machine for unidose liquid nasal devices. Capable of producing up to 100 devices per minute, the company’s UDS Vial Filling & Assembly System features a racetrack format with vibratory product feeding.

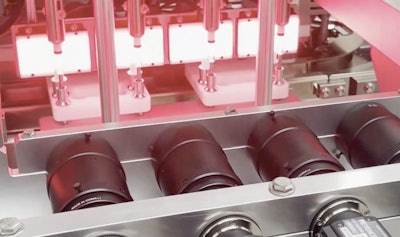

After an air jet and vacuum system cleans all vials, the UDS Vial Filling & Assembly System’s initial inspection station checks for cracks in each. To perform this step, vials are raised and rotated, allowing for 360-degree high-resolution camera inspection. The machine also can be equipped with a variety of additional upstream and downstream inspection capabilities, including safeguards checking for unstoppered vials, an enhanced lens for exacting fill height verification, and a push-pull station that tests the nasal device’s integrity.

Vision inspection of filled vial with stopper

Vision inspection of filled vial with stopper

Vials are filled via a series of precision valve-less ceramic piston fillers, whose volume can be set and calibrated electronically. Stoppers are inserted using a servo-controlled pick-and-place module featuring a burping tube to allow air escape during placement. Next, nasal actuators are introduced in-line via a vibratory feeder, and inspected to ensure cannulae are present and straight. The nasal devices are automatically placed around the vials, pressed into place with an automatic tamping system, and automatically transitioned to a labeling station with requisite serialization capabilities.

TurboFil’s UDS Vial Filling & Assembly System is both precise and flexible, and its microdosing prowess can meet or exceed accuracy tolerances of +/-2.5 microliters on a fill volume of 100-125 microliters. Stopper position can be determined down to 0.3 millimeters, ensuring device specifications are met. To bolster sterility, the unit’s product contact parts are composed of ceramic, 316L stainless steel and Teflon. All operations are performed via a 15” touchscreen HMI with recipe control and the ability to turn on or off any station or inspection as required for the particular application.

“With intranasal administration devices experiencing a tremendous growth curve, pharma manufacturers require solutions that can produce such intricate drug delivery systems not only effectively but also expeditiously,” said Deborah Smook, VP of Marketing & Business Development for TurboFil Packaging Machines LLC. “The UDS Vial Filling & Assembly System makes such efficiencies possible, and opens the door for pharma companies to consider producing medicines in a format where ease of use and direct dosage dispensing is fueling rapid expansion.”