Lachenmeier, part of SIG and a manufacturer of stretch hood equipment and film, offers solutions for the corrugated industry with its machine technology and Lachenmeier Xeros™ condensation control film.

The Multi FleXL machine and Xeros film were specifically designed with the industry in mind and both have become popular solutions worldwide for keeping loads secure and pristine.”

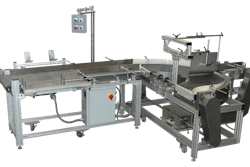

Multi FleXL stretch hood machine provides the necessary protection and force to stabilize even the most challenging loads. The machine wraps loads from500 x 500 mm and up to 3,200-mm long x 1,700-mm wide, with a maximum height of 3,000 mm. It can be configured with up to four different film sizes and be set up to automatically switch between sizes to provide enhanced flexibility and a perfect fit for every load. Wrapping up to 150 loads/hr, depending on the size and height of the product, Multi FleXL further provides fast and accurate results.

When coupled with Xeros stretch hood film, loads are not only quickly and effectively secured, but also free of contaminates and moisture. Stretch hood film inherently offers waterproof protection, ensuring loads are kept dry from the elements.

However, condensation can also build from the inside due to high humidity or drastic fluctuations in atmosphere temperature. The patented multi-layer film technology used to manufacture Xeros prevents that. The combination of proprietary features effectively manages sunlight and creates an impermeable barrier to liquids. Aside from eliminating condensation and unwanted elements from entering the bag, the technology also maintains barcode readability and prevents tears or punctures as bags are stretched over the load.

These systems are suited for manufacturers looking to secure pallet loads both during transport or when stored in the field. The system saves customers 10% in film consumption, is 100% waterproof, and eliminates the risk of contamination.