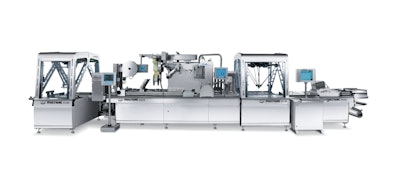

Multivac’s thermoforming packaging line gives customers the benefits of obtaining all the line components from one source: full integration of the line modules, the right interfaces, single uniform operator guidance, and one person to contact.

The packaging line consists of the R 245 thermoforming machine; the MRQ cross-web labeler, which is equipped with a TTO thermal-transfer printer; the MR822 checkweigher; a Multivac MBS 100 belt system; and an automatic stacking unit.

The high-output R 245 thermoformer is equipped with an MR293 TT direct web printer for printing directly onto the upper web. The R 245 is equipped with modules that ensure maximum flexibility and quick conversion to other pack formats. Among these are Multivac’s “drawer” system for the simple changeover of forming and sealing die parts, hinged side frames, and a film quick-change system. With the WW 220 die-changing trolley, the handling of the dies is made easier.

The speed and opening width of the R 245’s servomotor-operated lifting units can be accurately controlled. This enables the lifting unit’s movements to be matched perfectly to different film thicknesses. It also simplifies format change as the parameters can be stored in the thermoformer’s recipe storage.

The ergonomic R 245 is equipped with a Multivac HMI 2.0 user interface that allows for intuitive operation of the machine. The R 245 also has heated side frames, which make the workplace more pleasant for employees who are usually in a cool production environment.

The MRQ cross-web labeler and TTO thermal-transfer printer from Multivac Marking & Inspection have been optimized for use on Multivac packaging machines. Their operation is completely integrated in Multivac’s HMI 2.0 user interface.

The MR822 checkweigher also comes from Multivac Marking & Inspection. Its transport conveyor and weighing modules are mounted on a robust twin beam carrier, on which almost all configurations of different conveyor modules can be fitted. The entire construction is designed for maximum weighing accuracy with rigidity against flexing, reduction of vibration, and absence of torsion.

The Multivac MBS 100 belt system converges the packs after the sealing process. The automatic stacking unit can automate and significantly simplify the process of pack stacking prior to manual loading of the packs into boxes. The Multivac Pack Stacker can be integrated in the machine control of end-of-line modules. This enables uniform recipe management to be performed via production data acquisition (PDA) throughout the entire packaging line.