Videojet Technologies’ 8610 thermal ink-jet printer provides high-resolution print on nonporous packaging materials including films, foils, plastics, and coated stocks.

Incorporating a patented cartridge for industrial inks, including MEK-based printing fluids, the Videojet 8610 offers a suite of performance attributes for a thermal ink-jet system.

According to the vendor, there is a growing need for packaging professionals to in-line print multi-line codes and other high-resolution marks, including DataMatrix and QR codes, without modifying their packaging designs.

The 8610 uses industrial ink cartridge technology, which consists of a fully contained, high-resolution print cartridge designed specifically to jet MEK-based inks. Coupled with the automated Cartridge Readiness System, the 8610 print system is ready when the user is, regardless of the frequency or length of common line interruptions. The result is the ability to use fast-drying solvent inks, such as MEK, and still achieve clean, repeatable codes.

The 8610 offers near-letter quality printing with excellent edge acuity, addressing a longstanding need for manufacturers trying to print high-resolution marks on challenging substrates.

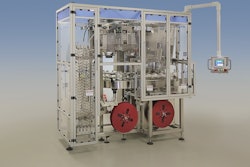

The Videojet 8610 print system comprises three main components: a controller with user interface, an industrial printhead featuring the Cartridge Readiness System, and a disposable ink-jet cartridge.

The 8610 has been designed to focus on usability. Maintenance is minimal and only requires an occasional wipe of the print array and the shutter. Ink replenishment is accomplished with a simple cartridge change, a task that can be performed in 15 seconds or less. Additionally, there are no wear parts to replace and no calibration or tuning required, thereby freeing up production personnel to focus on other line demands.

The 8610 design brings a new dimension to printer availability as each cartridge change provides a new print array, helping to ensure peak performance. And with on-board Code Assurance, the 8610 controller simplifies job selection and data entry, helping to ensure code accuracy by enabling operators to get the right code on the right product each time.