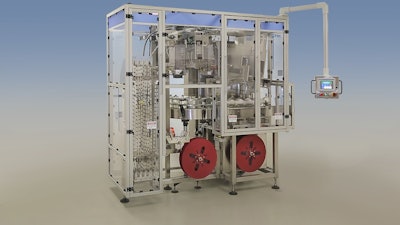

For products that need tamper-evident banding, PDC International Corp.’s 90C-ER shrink sealer is compatible with a broad range of package sizes and seals up to 400 cpm. Although the machine is engineered for speed and reliability, it is variable speed and runs as slowly as 50 cpm to synchronize with production requirements.

90C-ER shrink sealers apply single- and multilayer PVC, PETG, PLA, and OPS sleeves in gauges as thin as 40 microns. The compatible sleeve diameter range is .375 to 3.0 in., and the height range is .625 to 4 in.

PDC’s splice-on-the-fly changeover feature allows a second film reel to be staged and spliced while operation continues at normal speed, thus eliminating downtime for roll splicing. When the current reel is spent, an end-of-reel sensor automatically clamps the material end and begins consuming from the accumulation festoon. Once the splice is complete, the festoon refills by returning to its original position and awaiting the next roll change.

Standard features of the 90C-ER include stainless-steel frame, NEMA 4 enclosures, Allen-Bradley touchscreen and PLC, and static eliminator. There are sensors for low material and film feed as well as for imprint and barcode verification.

The 90C-ER has a robust blade assembly that allows blades to be re-sharpened at least three times and reversed, providing a long service life and cost savings. Systems also feature tool-less changeover, which minimizes downtime between format changes.

Both vertical and horizontal perforators may be added. As with all PDC shrink-sealing systems, heat tunnels and complete conveying systems can be supplied as part of an integrated package.

The 90C-ER shrink sealer pairs with PDC’s Smooth Diversion Inspection/Ejection System to confirm the location of bands and divert any packages that are out of specification. Large containers are diverted onto an adjacent rotary table. The AMS feature will stop the machine after a preset number of rejects.

PDC 90C-ER shrink sealers are available in UL- and CE-approved versions. The use of off-the-shelf components minimizes maintenance expenses throughout the system’s