When prominent companies such as Bayer, Johnson & Johnson, and Nestlé market products in stick packs, it indicates that the convenient, portable packs are gaining momentum in the U.S. To capitalize on potential stick-pack sales, Contract Pharmacal Corp. (CPC) recently invested in a 10-lane vertical form/fill/seal stick-pack machine from Viking Packaging Technologies, Inc..

CPC develops, manufactures, and packages solid-dose prescription pharmaceuticals,

over-the-counter drugs, and dietary supplements. It has commercialized 3,800 products since it was founded in 1971.

The company conducts its commercial contract manufacturing and packaging operations at its 175,000 sq-ft headquarters location in Hauppauge, NY. The facility houses 13 dedicated packaging lines: five for bottling, two for blister packaging, two for stick packs, two for powder pouching, one for tablet pouching, and another that handles powder filling. Approximately 50% of CPC's revenue comes from Rx/OTC sales, with the other 50% from dietary supplements.

CPC added the Viking machine last June. It runs on three shifts, with an output of approximately 125,000 sticks/shift.

“CPC consistently uses the industry's most advanced equipment to ensure the highest-quality products,” says Matt Wolf, CPC's CEO. “We chose the Viking stick-pack machine because it produces a high-quality, aesthetic product. It is a highly reliable machine that is easy to operate and ensures robust construction of the stick packs, consistent weight control, and efficient speed. As a result, CPC is better positioned than ever to offer customers stick packaging that showcases their brands while offering consumer convenience.”

Wolf praises Viking as a company, saying “Viking has a unique ability and knowledge to provide a stick-pack machine that fits our specific packaging needs, while offering us a strong tech-support team to assist us with ongoing maintenance.”

Adding the machine, Wolf says, has significantly expanded CPC's production capacity to

meet the growing demand for the stick pack, which he notes is increasingly becoming a more popular dosage form for customers overseas and in the U.S. “The Viking is our second stick-pack machine, and enables us to continue to provide high-quality stick packs to our customers worldwide,” he says.

Wolf believes the packs also help to:

• Attract consumers

• Deliver significant cost savings around initial investment and parts

• Offer easier setup and less changeover time, resulting in more production time

• Permit fast and easy machine adjustments.

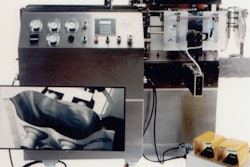

Vf/f/s process

During operation, product is poured into a main hopper above the vf/f/s machine. The hopper is equipped with a transfer drive assembly that ensures the correct amount of product is kept inside the filler hopper.

Inside the filler hopper, there is a set of 10 augers that is connected to a set of servo-driven motors from Siemens. The motors control each auger independently, enabling CPC to control the fill weight for each stick pack. Then the augers move the powder down through a filling tube.

The film unwinds through a set of rollers in the machine. As it advances, it is slit into the correct size for each of the 10 f/f/s lanes. Lot number and expiration date are printed onto the film by five two-head thermal-transfer printers from Markem-Imaje.

Wolf explains, “We partner with many industry-leading film suppliers,” running the following film structures:

• 92-ga PET/7.4# white low-density polyethylene (WLDPE)/70-ga foil/21# LDPE

• 48-ga PET/10#WLDPE/.000285 foil/18# Surlyn® from DuPont

• 48-ga PET/10#WLDPE/.0003 foil/1.75-mil polyethylene Surlyn coex.

Wolf says, “Stick packs are slowly gaining acceptance among U.S. consumers. Today's consumers are always on the move, and stick packs offer them a convenient option for carrying and consuming a single dose of a product. Brand owners in the OTC and dietary supplement segments are increasingly seeking to fulfill that growing need for products on-demand. Stick packs also are becoming increasingly popular among pharmaceutical companies seeking to provide children with easy-to-swallow remedies.”

A recent example of a product selling in stick packs is Bayer Aspirin Quick Release Crystals. Wolf says, “Bayer is one of the many pharmaceutical companies around the world with whom we have partnered to manufacture and package stick-pack products.

“There have been a number of stick-pack product launches in the dietary supplement space recently, including SlimQuick's fat burner, Airborne's immune health product, Mucinex Mini-Melts, Greens to Go drink mix supplement, and Benefiber's fiber supplement.”

Wolf notes that global consumer packaged goods companies are also developing stick-pack products, mentioning Kraft's Crystal Light, Johnson & Johnson's Splenda, and Nestle's Nescafe instant coffee. “Even Starbucks recently broke new ground with instant, 'ready-brew' coffee in a stick pack,” he adds.

-By Jim Butschli, Editor

CPC develops, manufactures, and packages solid-dose prescription pharmaceuticals,

over-the-counter drugs, and dietary supplements. It has commercialized 3,800 products since it was founded in 1971.

The company conducts its commercial contract manufacturing and packaging operations at its 175,000 sq-ft headquarters location in Hauppauge, NY. The facility houses 13 dedicated packaging lines: five for bottling, two for blister packaging, two for stick packs, two for powder pouching, one for tablet pouching, and another that handles powder filling. Approximately 50% of CPC's revenue comes from Rx/OTC sales, with the other 50% from dietary supplements.

CPC added the Viking machine last June. It runs on three shifts, with an output of approximately 125,000 sticks/shift.

“CPC consistently uses the industry's most advanced equipment to ensure the highest-quality products,” says Matt Wolf, CPC's CEO. “We chose the Viking stick-pack machine because it produces a high-quality, aesthetic product. It is a highly reliable machine that is easy to operate and ensures robust construction of the stick packs, consistent weight control, and efficient speed. As a result, CPC is better positioned than ever to offer customers stick packaging that showcases their brands while offering consumer convenience.”

Wolf praises Viking as a company, saying “Viking has a unique ability and knowledge to provide a stick-pack machine that fits our specific packaging needs, while offering us a strong tech-support team to assist us with ongoing maintenance.”

Adding the machine, Wolf says, has significantly expanded CPC's production capacity to

meet the growing demand for the stick pack, which he notes is increasingly becoming a more popular dosage form for customers overseas and in the U.S. “The Viking is our second stick-pack machine, and enables us to continue to provide high-quality stick packs to our customers worldwide,” he says.

Wolf believes the packs also help to:

• Attract consumers

• Deliver significant cost savings around initial investment and parts

• Offer easier setup and less changeover time, resulting in more production time

• Permit fast and easy machine adjustments.

Vf/f/s process

During operation, product is poured into a main hopper above the vf/f/s machine. The hopper is equipped with a transfer drive assembly that ensures the correct amount of product is kept inside the filler hopper.

Inside the filler hopper, there is a set of 10 augers that is connected to a set of servo-driven motors from Siemens. The motors control each auger independently, enabling CPC to control the fill weight for each stick pack. Then the augers move the powder down through a filling tube.

The film unwinds through a set of rollers in the machine. As it advances, it is slit into the correct size for each of the 10 f/f/s lanes. Lot number and expiration date are printed onto the film by five two-head thermal-transfer printers from Markem-Imaje.

Wolf explains, “We partner with many industry-leading film suppliers,” running the following film structures:

• 92-ga PET/7.4# white low-density polyethylene (WLDPE)/70-ga foil/21# LDPE

• 48-ga PET/10#WLDPE/.000285 foil/18# Surlyn® from DuPont

• 48-ga PET/10#WLDPE/.0003 foil/1.75-mil polyethylene Surlyn coex.

Wolf says, “Stick packs are slowly gaining acceptance among U.S. consumers. Today's consumers are always on the move, and stick packs offer them a convenient option for carrying and consuming a single dose of a product. Brand owners in the OTC and dietary supplement segments are increasingly seeking to fulfill that growing need for products on-demand. Stick packs also are becoming increasingly popular among pharmaceutical companies seeking to provide children with easy-to-swallow remedies.”

A recent example of a product selling in stick packs is Bayer Aspirin Quick Release Crystals. Wolf says, “Bayer is one of the many pharmaceutical companies around the world with whom we have partnered to manufacture and package stick-pack products.

“There have been a number of stick-pack product launches in the dietary supplement space recently, including SlimQuick's fat burner, Airborne's immune health product, Mucinex Mini-Melts, Greens to Go drink mix supplement, and Benefiber's fiber supplement.”

Wolf notes that global consumer packaged goods companies are also developing stick-pack products, mentioning Kraft's Crystal Light, Johnson & Johnson's Splenda, and Nestle's Nescafe instant coffee. “Even Starbucks recently broke new ground with instant, 'ready-brew' coffee in a stick pack,” he adds.

-By Jim Butschli, Editor