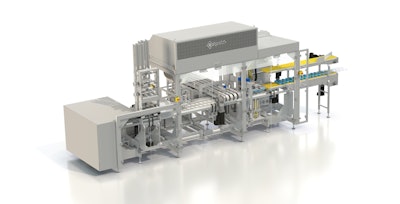

Well deserving of its tagline, “a new generation of cup filling machine,” the Versatech from Synerlink, a BW Packaging Systems Company, is a modular, ultra-flexible machine that can fill cups from 40 to 150 mm at 12,000 cups/hr, with changeover from one format to another, including different shapes, materials, diameters, and heights, taking just 20 min from last to first container.

One key to the flexibility of the system is its modular design, which allows functions to be added, switched, or removed easily and quickly—from half a day to two days, according to Fabien Jégo, design leader and product marketing leader at Synerlink S.A. Each module is plug-and-play via a centralized cabling network. Through this network, each module automatically integrates with the rest of the system, both pneumatic and electric. The indexed position of the modules allows for simple placement and calibration, with a positioning accuracy of 0.1 mm.

Another feature that facilitates this flexibility is the machine’s ability to automatically load and unload slats, which Jégo says allows the customer to perform a slats change “in record time.” It also allows for fast and easy cleaning of the slats, with no tools required. Another advantage of the system’s fast return system is that fewer slats are required.

According to Jégo, the Versatech was engineered to address the top six issues currently facing users of cup filling machines. One is late customization by brand owners. With the Versatech, “a project manager can place an order without having full specifications,” he explains. “The modular design allows final packaging design integration and functions modifications until the last minute.”

The second is a need for packaging versatility, as it allows a brand to respond to rapidly changing markets without having to wait for long lead-time machine redesigns. Shares Jégo, the potential, in terms of the range of cup sizes, shapes, and materials, that the Versatech can handle is infinite. “We can process any cup within the mechanical range of the machine [40 to 150 mm in dia and 160-mm high], from standard stackable to non-stackable cups in plastic, cardboard, and glass,” he says. “Moreover, if a new generation of cup arrives on the market, the modularity of the Versatech will allow us to develop new functions and to implement them on the machines already in production.”

The cup filler has also been designed to adapt to a customer’s changing requirements, negating the need for a packager to purchase additional equipment as their business grows. Says Jégo, “We can imagine that a yogurt producer who starts his business might equip himself with a basic machine, and later on, when his market has evolved, he might add capacities to his machine, such as decontamination of the cups with pulsed light, a second dosing device for a fruit coulis [fruit puree] at the bottom of the cup, or a snap-on lid.”

And, on the subject of flexibility, the fourth issue the Versatech addresses is the ability to handle mixed batches, especially for customers such as co-packers who are running smaller-volume jobs. “It has never been so easy to fulfill mixed orders for a production manager,” says Jégo, who cites the machine’s 20-minute changeover capability.

The cup filler also tackles issues around labor, such as ease of use and ergonomics. “It is very important for a site manager to limit the turnover of his operators and to keep the experienced people,” says Jégo. “Our machine is designed to be extremely convenient to operate. The loading of consumables, such as cups, lids, and toppers, is done at chest height.” In addition, loading can be done while the machine is running. High visibility throughout the entire production process ensures the correct functioning of the machine and adjustments to the slats’ changeovers, transparency, weight, and size reduces the risk of operator error.

The machine also meets a need for efficient maintenance. The Versatech uses clean, chainless servo technology to move the cups, which eliminates the need for grease used for lubrication and for readjustment of the chain over time. Maintenance operations are also aided by the machine’s easy disassembly and reassembly technology.

Synerlink particularly recommends the Versatech for applications that include dairy products, desserts, baby food, and fruits and vegetables.