ESS designed the new Model CE15 Robotic Case Erector and CS15 Modular Case Sealer to integrate easily with existing case packing lines. Both the case erecting and case sealing modules offer a compact footprint to reduce the required factory floor space. ESS can design the system to facilitate either manual or automated case loading. The CE15/CS15 Case Erector/Case Closer are ideal for use in packaging pharmaceuticals, nutraceuticals, cosmetics, and consumer goods, offering small- and mid-sized packaging facilities a cost-effective, space-saving solution for automated case erecting and sealing.

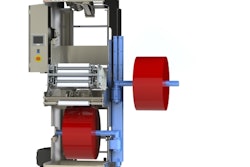

The CE15 Robotic Case Erector integrates a FANUC M-10iA robot with custom, ESS-designed end-of-arm tooling (EOAT) to create a compact case erector that produces up to 15 cases/min. The robot picks a case from the ergonomically designed case magazine and uses the special EOAT to square the case sides. The robot then runs the case across a bottom closer and sealer before placing it on the case transport conveyor. Case bottoms may be secured with 2 in. tape (standard) or hot melt glue (optional). The case then conveys to a manual or automated loading station, or the CE15 may be integrated with new or existing case loading systems. The CE15 robotic case erector is ideal for heavy-duty cases and provides excellent repeatability while offering long-term durability and unprecedented MTBF statistics. Few moving parts and simple tool-less changeover enhance productivity and uptime.

After loading, cases convey to the CS15 Case Closer and Sealer module. The top flaps of the case are closed and the top is sealed with 2 in. tape (standard) or hot melt glue (optional). The CS15 integrates with the case loading system as well as labelers, shrink wrappers, case checkweighers, and robotic palletizing systems to create a complete case packaging line. Both systems use Allen Bradley controls and include a color touchscreen HMI.

To meet serialization requirements for pharmaceutical manufacturers, ESS works with serialization system OEMs to seamlessly integrate coders, labelers, and inspection systems to create a solution for track-and-trace case packing applications. ESS has installed dozens of serialization-enabled case packers in North America and has worked with all industry leaders in serialization systems. ESS now offers three-to-five-months shipment of serialized cartoners, case packers, and robotic pallet cells, depending on the machine and application.