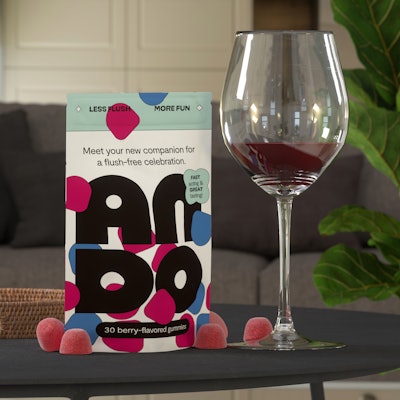

Ando, an anti-Alcohol Flush gummy, was created to counter the symptoms of Alcohol Flush, which include redness, itchiness, dizziness, and nausea, and affect over 15 milllion Americans. Recently launched in a standup pouch with a resealable zipper along the tearline, the pouch has a soft texture and matte finish.

The design’s aesthetic is meant to capture a joyful experience through a bright and fresh color palette, with logo styles and illustrations full of personality in a market typically dominated by monochromatic packaging, says Raylen Margono, co-founder of Ando. The anti-flush market is also mainly comprised of patches and pills that are not as easily accessible.

Margono sought packaging that would fulfill the functional requirements of a 30-gummy pack while maintaining affordability for his customers. About a dozen suppliers into its search, the company chose one based on its exceptional customer service, product offerings, and favorable unit economics. Ando found its contract packager (CP) through word of mouth from its supply chain partners. The gummies are shipped direct-to-consumer through the CP and formulation house, who handled packaging and shipping.

| Top 3 Most Pressing Issues and Solutions as CPGs Move to Sustainable Packaging |

Margono says the packaging outcome exceeded the company’s expectations and met all its design criteria reflecting a fun and positive experience. Prior to product launch, Ando tested the packaging through focus groups to gather consumer feedback and implement necessary changes.

“In our approach, we started with an online Figma prototype to assess the language, voice, and visual design. We then partnered with a sample shop to produce 100 low-cost samples, allowing us to test the packaging's user experience before committing to a large-scale production order,” says Margono.

The ability to overcome hurdles is key in commercializing a new product. The company ran into copy issues prior to launch, compounded by the production order being run during the holiday season, “It looked like out packaging was going to have a delayed delivery to our copacker due to the changes and [that] our customers were going to have their orders late,” explains Margono. “Lots of coordination amongst our different suppliers, our copackers, and making our customers happy with discount codes were needed to get our orders to customers with these challenges!”

Margono offers the following advice to new companies entering the market.

“It's crucial to understand your target customers and design your packaging to resonate with their preferences, values, and lifestyles. Testing the packaging through focus groups or surveys is essential, as their feedback is invaluable for fine-tuning the final design.”

| Protect Your Sterile Barrier System Rollstock |